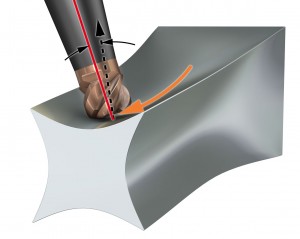

When it involves sinuate surfaces, swish finishes area unit important. Super-NURBS may be a programming practicality for CNC machining that meets high-accuracy end needs whereas rushing up cycle times. The result’s drastically reduced hand-finishing time to realize high-quality components quickly. Users will deliver components out the door quicker, with higher end quality and accuracy. Super-NURBS is suited to components with high-accuracy needs, like those for mould, die and aerospace or defense.

The term “NURBS” is a descriptor for Non-Uniform Rational Basis Spline. This was developed within the Fifties as a mathematical thanks to regenerate freeform curves and shapes like automobile bodies and ship hulls. It became ordinarily utilized in most CAD package packages, in conjunction with CAM systems, and is an element of business standards like IGES and STEP files.

The “Super” denotes the next degree of accuracy once the surface being machined has advanced shapes or massive changes of diameter among a brief linear distance. With Super-NURBS, it comes all the way down to dominant — and shortening — the electric circuit.

Super-NURBS may be a proprietary technology for achieving NURBS practicality among a CNC machining setting. With Super-NURBS, the CNC machining management comes a preset tolerance band that makes a spline thought of to be the most effective suitable the work. This eliminates redundancies and permits for a quicker and sander tool path. With less information to crunch, movement’s area unit sped up — whereas maintaining a high level of accuracy to come up with high-quality surface finishes.

Super-NURBS is in a position to deliver high speeds and quality finishes. this is often due partly to its foundation within the mechatronics approach, the mixing of mechanical and electrical development to assure optimized communication between the machine and its management. Super-NURBS additionally delivers the benefits:

Faster management Loops Speed: The feedback circuit determines however quickly the CNC machine will “talk” to the encoder and servo units. With Super-NURBS, the machine is quicker in telling the servo wherever to maneuver, and in receiving confirmation of obtaining data, letting additional ultra-high feedrates to be used. At times, this could involve “talking” to as several as 5 servos at the same time.

Digital-to-Digital: whereas controls area unit digital, several machine tools within the trade still use analog. this needs translation activity that slows down the CNC machining method. With machines outfitted with Super-NURBS, the management loops feed is digital-to-digital, that quickens the communications method and thus permits for quicker machining. there’s no would like for a look-ahead at intervals a Super-NURBS system as a result of it’s inherently quick while not it.

Machine Build Quality: the whole package of machine and management, together with the machine’s build quality, enhances overall practicality. Super-NURBS edges from machines with ribbed castings for strength, giant base casting with three-point leveling, integrated ballscrew mounts to confirm rigidity, cantilevered column to scale back weight and resist bending, handscraped solid coupling surfaces for superior flatness and speak to, and a piece space basined in sheet to eliminate hot chips and agent from contacting castings, that minimizes thermal influences.