Check out these wire edm China machining images:

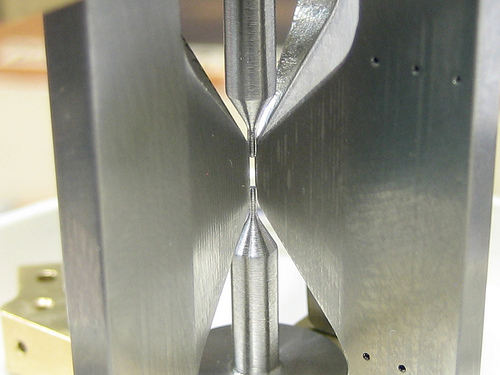

Tight trap, mockup, closeup

Image by fatllama

Group member Simon Webster has been designing a new linear ion trap to replace an old experiment. This version features a brass mounting structure instead of ceramic, which won’t work at all, but can survive various forms of abuse: dropping, prodding with metal tools, and being used as a jig for bending and assembling wires to be used as compensation electrodes.

Parts for the real trap are seen here. A view of the whole assembly is here.

The parts were made by Simon Moulder and the rest of the Motorcycle club at the Clarendon workshop using wire-erosion EDM China. The blades and endcaps are stainless steel, the insulators are Macor ceramic.

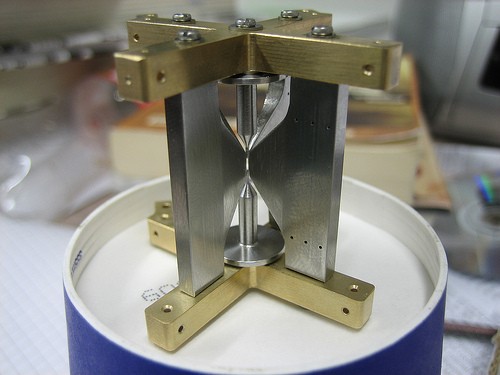

Tight trap, mockup

Image by fatllama

Group member Simon Webster has been designing a new linear ion trap to replace an old experiment. This version features a brass mounting structure instead of ceramic, which won’t work at all, but can survive various forms of abuse: dropping, prodding with metal tools, and being used as a jig for bending and assembling wires to be used as compensation electrodes.

Parts for the real trap are seen here. A closeup of the trapping region is here.

The parts were made by Simon Moulder and the rest of the Motorcycle club at the Clarendon workshop using wire-erosion EDM China. The blades and endcaps are stainless steel, the insulators are Macor ceramic.