All about Custom Machining

Custom machining is so much a part of our day and age, that plenty of people by no means even give it a believed. On the other hand, our modern day world wouldn’t be in which it can be nowadays without having this valuable process. Custom machining processes are utilized to create just about almost everything which is made from metal. Engine parts and tools cannot be created without making use of this course of action. It is utilized to create metal components for many issues apart from these pointed out.

It’s not only metal that rewards from custom machining, but it is employed inside the production of timber components of all kinds also. Anything from window blinds and shutters to windows, doors and cladding items are made using this method. Actually the process can also be utilized to produce plastic elements for a wonderful quantity of items. Definitely, just about anything that is certainly created from any substance is often stated to undergo the custom machining method.

It is actually utilised to manufacture the tiniest elements that may well be used for lifesaving devices this kind of as pacemakers, elements that go into mobile phones and elements for electronic equipment of all sorts as well as huge elements far bigger than a man. These parts is usually for large ocean liners, buildings, mining and agricultural gear, plumbing supplies, optical devices and for use in aerospace industries – you name it and it’ll happen to be machined to specific specifications.

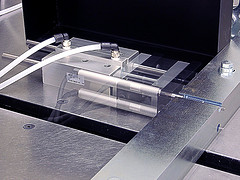

So what kind of tools and equipment are required for the course of action? Lathes are certainly one of the principle tools which can be a great deal made use of to manufacture custom parts and accessories. You’ll be able to get distinctive lathes for metal and for timber. Typically they are automated to make sure that no human error ruins the complex procedure required for creating intricate elements. They operate with computers and software program created to operate out the precise measurements and almost everything else that is definitely necessary to create the appropriate custom parts.

CAD or CAM software will allow the components to be created and even worked in 3D to find out if they’re of the right design and capability before any prototypes are produced. This saves both time and expenses, as in the event the component just isn’t the suitable size and shape it might then be re-designed right up until the style engineers realize that it is right. Many specialist machinists and technicians are necessary to get the job done together on creating this kind of components.

Obviously there are various other varieties of machines which can be applied to create all kinds of factors and that use custom machining to try and do so. Laser technological innovation assures that the many measurements are perfect and has been utilised to excellent impact to conserve time and funds by gaining it right the very first time. As contemporary engineering improves such services are provided at growing ranges of efficiency all of the time, making it attainable to style and make even more intricate items.

Hunting back, it isn’t that a lot of years ago due to the fact such factors would happen to be unattainable to produce, but with the many new machines coming into production each of the time, who knows what is going to be possible within the long term?

Colleen is a retired project manager, she has great experience in construction supervision, on site engineering and power generation. Also once being in charge she has dealt with labour hire. She now writes a variety of articles with the objective being to help provide tips and advice to others in the field.