Verify out these electrochemical machining pictures:

Image from web page 53 of “Electrochemical and metallurgical market” (1905)

Image by Web Archive Book Images

Identifier: electrochemicalm3190unse

Title: Electrochemical and metallurgical industry

Year: 1905 (1900s)

Authors:

Subjects: Electrochemistry Chemistry, Technical Metallurgy

Publisher: New York : [Electrochemical Pub. Co.]

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Pictures: All Images From Book

Click right here to view book on-line to see this illustration in context in a browseable on the internet version of this book.

Text Appearing Ahead of Image:

the wheels arc utilized as drivers, hence securing a max-imum tractive efTort and a duplication of mechanism. TheI- made by the Wcstinghousc Electric Co., their clcc- t- ■ iicy Ixring high. In the Electrical energy Kuilding the comj>any was exhibiting ar.i-Kht-linc electric hoist, with each other with photographs ofwhich have been equipped with their coal-handling ma-ry, a line of manufacture in which the business was thepioneer. LIEBIG S LABOUATOKV IN (.KK.MAN (.IIE.MKAL EXIIIHITION. Co., St. Louis Lidgerwood Manufacturing Co., New York,Niles-Bement-Pond Co., New York Robbins Conveying BeltCo., New York Westingliousc Machine Co., Pittsburg, Pa.R. D. Wood & Co., Philadelphia, Pa. Henry R. Worthing-ton. New York. Gold Medals.—Buffalo Forge Co., Buflfalo, N. Y. BuildersIron Foundry, Providence, R. I. A. S. Cameron Steam PumpCo.. New York Carbonnidum Co.. Niagara Falls, N. Y.Dearborn Drug & Chemical Organization, St. Louis De LavalSteam Turbine Co.. Lombard Governor Co.. Bostcin, Mass.

Text Appearing After Image:

EXIIIIIIT OF GOLDSl H.MIDT THERMIT CO. Lunkenheimer Co., Cincinnati Aug. Mietz, New York Mictz& Weiss, Nfw York Norton Emery Wheel Co., Worcester,Mass. Otto Gas Engine Co., Philadelphia Weber Gas &Gasoline Engine Co., Kansas City, Mo. Societc De Laval,Paris, France. .fint-s and Mctallurgy. Grand Prizes.— E. G. Acheson,Niagara Falls, N. Y. Allis-Chalmcrs Co.. Chicago. III.: Amer-ican Coal Items Co., New York Austin ManufacturingCo.. Chicago, III. Baker & Co., Newark, N. J.: Bethlehem.Steel Co., South Bethlehem, Pa. Canadian Copper Co., Sud-bury. Ontario: Dubois, Pinard et Cie.. Sougland, par Saint-Michel, Arsne. Goldschmidt Thermit Co., New York Inter- January, 1905.] ELECTROCHEMICAL AND METALLURGICAL Market. national Acheson Graphite Co., Niagara Falls InternationalNickel Co., New York Julian Kennedy, Pittsburg, Pa.Koenigliche Porzellan Manufaktur, Berlin, Germany LanyonZinc Co., St. Louis, Mo. A. Leschen & Sons Rope Co., St.Louis, Mo. Mangane

Note About Pictures

Please note that these photos are extracted from scanned web page pictures that may have been digitally enhanced for readability – coloration and appearance of these illustrations may not perfectly resemble the original operate.

Image from web page 251 of “Electrochemical and metallurgical business” (1905)

Image by Internet Archive Book Pictures

Identifier: electrochemicalm3190unse

Title: Electrochemical and metallurgical industry

Year: 1905 (1900s)

Authors:

Subjects: Electrochemistry Chemistry, Technical Metallurgy

Publisher: New York : [Electrochemical Pub. Co.]

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Photos: All Images From Book

Click right here to view book online to see this illustration in context in a browseable on the internet version of this book.

Text Appearing Ahead of Image:

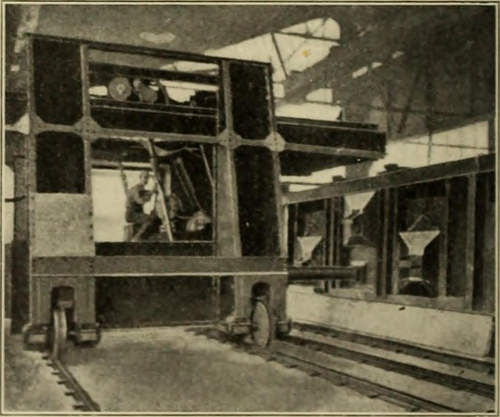

erts the plate in the charging opening of the furnace,holding it there in proper position until the repairs arecompleted, when it is withdrawn and detached from theram of the charging machine.The arch-plate serves a double purpose.Very first, it types a shield against the heat from theinterior of the furnace, hence enabling the operate of re-pairing the arch to be carried on without shutting downthe furnace. In the old approach of repairing arches ithas been necessary to build a temporary defending wallor bulkhead of brick, and on account of the heat thismust be carried out with extended-handled tools, creating the pro-cess not only awkward and tedious, but also expensive,as it necessarily delays the furnace. The use of theJohnson arch-plate does away with all this. Second, the Johnson arch-plate serves as a kind onwhich the arch can be expeditiously relaid, supportingit for the duration of construction. The flange serves as a quit forthe brick in laying the arch. Perform which would ordinarilv call for hours in the old way

Text Appearing Soon after Image:

JOHN>o .K( H-IM..TK IN I SE. can. by employing this arch-pfate. be accomplished in a tiny fraction ofthe time, even though the charge of steel is being melted down andwithout anv delav to the furnace. An Improved .Multiple-Rider Carrier. The accompanying illustration shows an improved numerous-nder carrier for button balances, just placed on the market place byWilliam .-Ninsworth & Sons, of Denver, Col The weights or riders are each and every carried by an individual arm June, 1905.] ELECTROCHF.^^TC.L AND METALLURGTCAI. Market. 245 and cannot grow to be displaced except by means of gross careless-ness. The arms are numbered in their front surfaces to corre-spond with the weight of the rider carried, and pivoted atthe rear, so as to just swing clear of the comb-shaped barbelow the stirrup, andare operated by asingle rod with athumb piece on theend of it extendingthrough the case.When the arms areup the riders are auto-ried 1) them farenough above thecomb-shaped bar soas not to interferewith the oscillationsof the

Note About Photos

Please note that these images are extracted from scanned page photos that could have been digitally enhanced for readability – coloration and look of these illustrations may possibly not perfectly resemble the original operate.

Image from page 429 of “Electrochemical and metallurgical sector” (1905)

Image by Net Archive Book Photos

Identifier: electrochemicalm3190unse

Title: Electrochemical and metallurgical sector

Year: 1905 (1900s)

Authors:

Subjects: Electrochemistry Chemistry, Technical Metallurgy

Publisher: New York : [Electrochemical Pub. Co.]

View Book Web page: Book Viewer

About This Book: Catalog Entry

View All Images: All Photos From Book

Click here to view book online to see this illustration in context in a browseable on-line version of this book.

Text Appearing Ahead of Image:

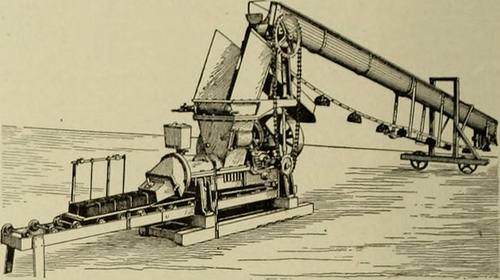

type. Nevertheless,the general procedure is to vaporize the quantity of waterremaining by a slow heat and leave the briquettes in the hard,bone-dry state in which the greatest efficiency is shown. Should of the niacliuies knead the i)consume as it is taken fromthe bog, taking it up in an elevator or chain of buckets tothe mixer, and then it is forced by way of a mouth piece, whichgives it the shape of the briquette and chops them off at agiven length. This block is referred to as compressed peat (Ger-man prcsstorf). It is wet and soft, and is passed on in thisstate to a drying table or plain. The initial of these machineswas constructed in 1861. by C. Schlickcysen, in Berlin. Themodern machines are all modifications of his design and style. The Schlickcysen method may be described as follows:Raw turf comes up on an endless belt running in the long,sloping trough which leads to the peat bog (for these ma-chines are normally transportable, and set up on the edge of thebog and moved from a single pari to (he f)tlKr as the function of

Text Appearing After Image:

SCHLICKEYSEN BRIQUETTE MACHINE. taking the peat out progresses). From the summit of theelevator the raw material drops into the machine, exactly where itis kneaded, cut, torn and compressed into about two-thirds ofits original bulk, and delivered at the mouth of the machinein blocks or bricks of any desired size or shape. These arefirst dried till they drop about two-thirds of their water, andthen the drying is continued by artificial means till they arebone-dry. Jhe principle upon which this machine is operateddepends on the reality that peat is nearly 80 per cent water in its(.riginal state, of which 4-fifths is held in mechanicalsuspension amongst the hairy fibers, and the remaining fifthis contained in the capillary tube running by means of the hairyvegetable fibers of the peat. Nine cubic feet Of raw peat istbus converted by this machine into 6 cubic feet of jireparcdpeat which nevertheless consists of 20 per cent water. This is furtherriried and compressed into i cubic foot of black, fossil-vege-ta

Note About Pictures

Please note that these photos are extracted from scanned page images that may have been digitally enhanced for readability – coloration and appearance of these illustrations may not completely resemble the original operate.