Some cool machining forged components images:

Image from page 71 of “Hardening, tempering, annealing and forging of steel a treatise on the sensible therapy and functioning of higher and low grade steel ..” (1903)

Image by Internet Archive Book Images

Identifier: hardeningtemperi00wood

Title: Hardening, tempering, annealing and forging of steel a treatise on the sensible therapy and working of higher and low grade steel ..

Year: 1903 (1900s)

Authors: Woodworth, Joseph Vincent, 1877-

Subjects: Steel Forging Tempering

Publisher: New York, N. W. Henley & Co.

Contributing Library: The Library of Congress

Digitizing Sponsor: The Library of Congress

View Book Web page: Book Viewer

About This Book: Catalog Entry

View All Images: All Photos From Book

Click right here to view book on the internet to see this illustration in context in a browseable on the web version of this book.

Text Appearing Ahead of Image:

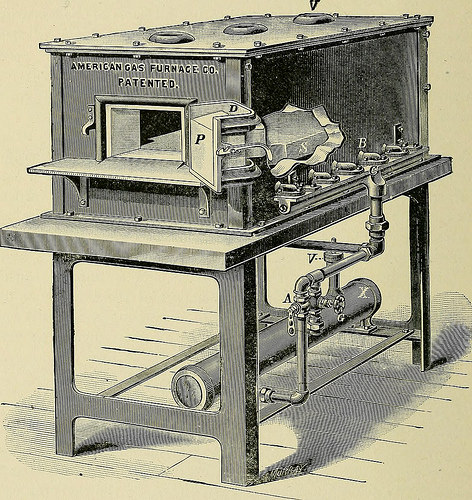

ugs, P, which are inserted and withdrawn by the cast iron automobile-riers, D. As their name indicates they are mostly employed for theprocess of case-hardening in cast-iron boxes, but also for anneal-ing heavy steel dies, hubs, tool steel, and so forth. The slab which dividesthe combustion chamber from the heating chamber is heavier thanin oven furnaces, properly supported by brickwork to bear heavyweights, and cast-iron rails are placed over the slab on which theboxes are removed in and out. The burners, B, cover the whole length of the heating spacethe opposite burners are connected to one particular gas and a single air valve, 68 HARDENING^ TEMPERING AND ANNEALING. which handle the provide. The door plug, P, is of the exact sizeand thickness of the entrance, so that it can be very easily inserted orremoved by cast-iron skeleton door, D. The positive aspects of gas blast case-hardening furnaces are thatthey do operate much more rapidly and completely than in the greatest ofcoal ovtos in use, since from the beginning of the operation all

Text Appearing Right after Image:

FIG. 37.—CASE-HARDENING FURNACE. the boxes inserted—and all components of each and every box—are heated sim-ultaneously and alike, and that the heat can be kept continual at themaximum degree which the cast-iron boxes will stand. Theseadvantages shorten the process materially, and when when thetime necessary for a provided amount and kind of perform has been as-certained, the exact same outcome can be developed thereafter, in the sametime. HEATING STEEL GAS BLAST FURNACES. 6q ^Heating Machine for Hardening the Edges of Mozver Blades.The machine shown in Fig. 39 is utilized for hardening the edgesof mower blades, and will operate as rapidly as the blades can bedropped into the jaws of the hyperlink belt K at I. The jaws are soformed as to expose only the edge of the blade as far as it is to behardened, to the action of the heat, whilst the physique of the blade is

Note About Pictures

Please note that these images are extracted from scanned page photos that could have been digitally enhanced for readability – coloration and appearance of these illustrations may not perfectly resemble the original work.