Industrial Gears: vitality of machine

Motivation is highly necessary in life and makes us to move ahead. Getting up in the morning for the work needs an inspiration, this can be about performing well or for satisfying monetary needs. Some sought punch is vital for the functioning and perform well in the daily task. Likewise, machines also need driving force to operate and serve their functionality. There are certain components and parts which are considered as most sought after way to give motion to the machines. Gear is a projection of the machine part which get inter connected with the other projected part and is responsible for movement and also changes the velocity of the machines.

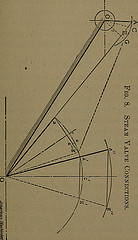

Gears have very broad scope of utilization in every industry. They are made up of different gear materials. Steel, Aluminum, wood, copper and various other gear materials are present which are used in galore of fields. Gear materials are also opted on the basis of worked they deliver, for instance if gear houses in the high capacity machine then a gear material made of carbon, steel are the correct choice. On the other hand gears of big precision demands the material which has lesser strength and hardness rating. Similarly, there are external and internal gears. An Internal gear has the formation of teeth in the inner surface of a cylinder or cone. For instance bevel gears, which is an internal gear having pitch angle exceeding 90 degrees. On the other hand, in external gear formation of the teeth takes on the outer surface of a cylinder or cone.

Gears are considered as the most important assistance in the modern days’ machines and this being the reason that industrial gears have paved their way in many sectors. And one can found different types of gears which are present in the industries due to their unique nature and also the delivery made by them. They can be considered as the soul of the machines which actually make them to move.

Since industrial gears are present in almost every sector, huge applications of gears with high torque capacity can be witnessed in automotive industry. The gear used effectively converts into mechanical energy very smoothly and without noise. Applications of gears can also be found in vessels like ferry boats, work boats and luxury yachts. These are called as Marine gears and are generally very powerful so that they can meet the needs. Even agricultural industry cannot remain untouched without the utilization of the gears and are called as Agro gears and are used in the process of tilling, seeding, sloughing and in irrigation purposes. The tractor also makes use of gears which are usually spurring and helical gears. They are also used in the conveyor belts which are used to transport things from one place to other using conveyor gears. Rack and pinion gear transform rotation into linear motion. Steering system on many cars also make use of pinions.Gears are lifeline of the machines and enjoy the immense and rich presence. They are like the building blocks of the every industry.

Hi! I am an active writer since four years and involved in providing the readers with the complete information about the Precision Gears.

[youtube http://www.youtube.com/watch?v=_PIr3dwedMM&fs=1&rel=0]

Gears and Gear Cutting China and Manufacturing China – Mechanical Manufacturing China Gear Functions Gear Cutting China & Machining China Methods Visit Al Ferdos Engineering China Workshop, Al …

Related Gear Machining China Articles