A handful of nice precision cutting images I identified:

Strap-on Video, take three

Image by jurvetson

This shiny new LOC Expediter rocket is ready for induction into the Telstar Logistics fleet. It has been heavily reinforced to take the stress of huge motors and a strap-on video camera to catch the launch action.

For example, I Kevlar-wrapped the body tubes (the reduction coupler shows it unpainted) and fiberglassed the fins, tip-to-tip. The battery connections are soldered. I utilized a custom motor tube than runs up by way of the yellow coupler

To streamline the videocam cylinder, I glued half of a plastic Easter egg on leading and fiberglassed the seam.

And the laser-cut vinyl flames come from GraphixnStuff. I met Dave at BALLS and was delighted to see a website dedicated to rocket decoration!

This will be my third camera to attempt to survive the g-loads of launch and the mishaps of reentry. The 1st 1 shredded on a V2 + K700 motor. Right here is a “successful” Norad flight photo and video from camera #2 on an H210 motor (the next launch became a ballistic lawn-dart into the Black Rock Desert). This Expediter kit is a scaled up version of that earlier Norad rocket, and I will attempt successively larger motors to test its limits (J350, K550, L730… see ya! That last motor would undoubtedly eliminate the camera as RockSim shows it screaming by means of Mach1… need to have a plan for that =)

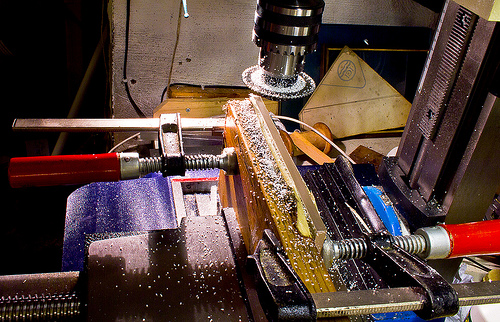

Cutting Perspex

Image by tudedude

Support the material reduce with wood supports, Set the material and blade to reduce toward the backing.

For thin material spot the wooden backing so that the blade in fact cuts into the backing slighly. Use extremely slow cutting speeds.

Cutting Perspex with a Slitting Saw

Image by tudedude

Cutting perspex or most plastic variety material needs to be accomplished with extremely slow cutter speeds.

Cut as well rapidly and the material will melt! jam! and occasionally break the cutter.