These days, the manufacturing industry is going through a digital transformation. We are seeing fresh business models geared towards meeting the demand of customers. For making progress in today’s competitive world, businesses are innovating production processes. Most of them are accepting new processes for manufacturing, such as 3D printing through CNC machining services. Read on to know more.

Nowadays, medical devices are being made with these machines. And we often read articles about these things in newspapers. With the help of automated apps and fast milling tools, these machines play a great role in the digital manufacturing world in a host of industries. The delivery is quite fast.

While CNC making isn’t as popular as the 3D printing, it has been used in a number of projects in different industries. For instance, it’s used in the making of custom-machined aluminum-joint based housings.

At Skyven Technologies, for instance, CNC machined parts are an important part of a solar panel system for the generation of electricity.

Spartech is another good example. They use CNC machining components in order to check the design of parts that are used in motorcycles, utility vehicles and snowmobiles.

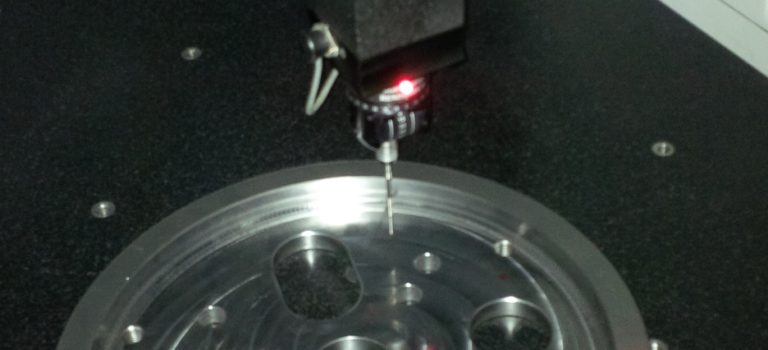

Unlike 3D printing, CNC machining is not an additive process. It cuts into plastic and metal in order to develop components and prototypes. Although it’s a bit different from the 3D printing, it offers similar benefits to a variety of businesses, especially those that are involved in mass production of different machinery parts.

This system can be used when you need small batches. However, at this level, it’s more economical to make small batches. This is one of the main reasons why this system is popular in the mass production industry. It’s used in the commercial-grade machinery and equipment.

So, the main advantage of using the process is to producing tons of parts using a variety of materials for testing functions.

There is no doubt that the parts manufactured with the help of high-speed milling are different from those of molded ones. This results in quality prototypes that you can use as fixtures, one-offs and jigs. We can say that CNC machining is one of the best processes to make end-user components.

Meeting tough challenges

The use of 3D printing and CNC machining doesn’t have to be exclusive. The technology can be used as an add-on for tuning the objected. Aside from this, its use can’t be restricted to bigger companies only.

It’s possible to apply two processes at the same time in order to meet the challenges, such as the demand for lightweight parts and objects that have complicated geometries. So, in such situations, businesses can improve the flexibility through CNC machining.

To cut a long story short, CNC machining can be used for speeding up mass production. Aside from this, it’s used to cover the increasing demands of customers. Although the 3D printing is rising in popularity, CNC technology is not far behind. We should try to raise more awareness about this technology so that more and more businesses could adopt it.

Resource box:

Are you interested in CNC machining technology and thinking of using it for your business? If so, we suggest that you give a go to a CNC milling company in China.