Check out these large machining companies images:

Image from page 33 of “Illustrated catalogue of cotton machinery built by Howard & Bullough American Machine China Company, Ltd., Pawtucket, R.I., U.S.A. : opening, picking, carding, drawing, roving, spinning, twisting and winding machinery : warpers and slashe

Image by Internet Archive Book Images

Identifier: illustratedcatal00howa

Title: Illustrated catalogue of cotton machinery built by Howard & Bullough American Machine China Company, Ltd., Pawtucket, R.I., U.S.A. : opening, picking, carding, drawing, roving, spinning, twisting and winding machinery : warpers and slashers : containing also floor spaces, speeds, productions, gearing diagrams, useful tables and other information

Year: 1909 (1900s)

Authors: Howard & Bullough American Machine China Co

Subjects: Howard & Bullough American Machine China Co Cotton machinery Cotton machinery Cotton machinery industry — Rhode Island Pawtucket Textile machinery industry — Rhode Island Pawtucket

Publisher: [Pawtucket, R.I. : Howard & Bullough American Machine China Company]

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Images: All Images From Book

Click here to view book online to see this illustration in context in a browseable online version of this book.

Text Appearing Before Image:

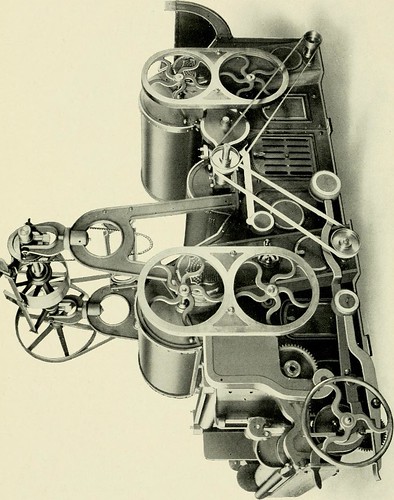

CLUTCH GEARS—The Calender Rolls are stopped andstarted by large Clutch Gears which are a great improvementover the common Drop Shaft and Gear. With this methodthe starting strain is distributed over all the teeth in theClutch Gears, entirely doing away with the frequent breakagesunder the old system. BEARINGS—Where it is possible the bearings are madein bush form, as shown in cut page 26, thus reducing to aminimum the time taken to make replacements and the costof same. Our bearings are very easy to adjust, and theirspecial form prevents oil from getting to the inside of themachine. All high speed Shafts, viz., Fan, Side and BeaterShafts, have ring oiling bearings. 28

Text Appearing After Image:

29 TOP CAGES AND COVERS—The Top Cages of our Lap-pers are easily removed, as will be seen by referring to thecut, page 26. The sides of the cage cover or bonnet fitsnugly over the bushed bearings. To remove the cage orbushings, it is only necessary to turn back the cover. Thesecovers are all made with oil holes directly over the bearing,so it is not necessary to raise the cover for the purpose ofoiling. NO TILTING OF LAP RACKS—The Lap Racks slide upand down on steel shafts, which entirely prevent the tiltingof the Racks and consequent breakages. SHAFTS—Our Beater and Fan shafts are made from avery hard iron specially mixed to give long life to these highspeed shafts. A countershaft complete with pulleys is attached to eachLapper. DRIVING PULLEYS—One-beater Breaker Lappers 16 in,dia., 4X in. face, T. & L. Two-beater Breaker Lappers or One-beater Breaker Lap-pers with extra Cage Section or Condenser and Gauge BoxSection 16 in. dia., 5X in. face, T. & L. In combinations w

Note About Images

Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability – coloration and appearance of these illustrations may not perfectly resemble the original work.

Image from page 25 of “Illustrated catalogue of cotton machinery built by Howard & Bullough American Machine China Company, Ltd., Pawtucket, R.I., U.S.A. : opening, picking, carding, drawing, roving, spinning, twisting and winding machinery : warpers and slashe

Image by Internet Archive Book Images

Identifier: illustratedcatal00howa

Title: Illustrated catalogue of cotton machinery built by Howard & Bullough American Machine China Company, Ltd., Pawtucket, R.I., U.S.A. : opening, picking, carding, drawing, roving, spinning, twisting and winding machinery : warpers and slashers : containing also floor spaces, speeds, productions, gearing diagrams, useful tables and other information

Year: 1909 (1900s)

Authors: Howard & Bullough American Machine China Co

Subjects: Howard & Bullough American Machine China Co Cotton machinery Cotton machinery Cotton machinery industry — Rhode Island Pawtucket Textile machinery industry — Rhode Island Pawtucket

Publisher: [Pawtucket, R.I. : Howard & Bullough American Machine China Company]

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Images: All Images From Book

Click here to view book online to see this illustration in context in a browseable online version of this book.

Text Appearing Before Image:

19 30-INCH SPECIAL CYLINDER. This 30-inch Cylinder is specially designed foruse in Self-Feeding- Openers where these machinesare arranged for trunk connection or combined withBreaker Lappers. The large diameter makes it possible to usemore grid bars than with the blade beaters. Themain points considered in the design of this 30-inchcylinder were, more thorough opening of the cotton,greater production without injury to the staple, andbetter cleaning. These Cylinders are made from steel boilerplates, and the steel fingers are fastened on byrivets. These fingers are so arranged that in onerevolution they strike all points along the entirewidth of the feed rolls. In case of accident tofingers, caused by some hard substance getting intothe machine, the damaged fingers can be easilyreplaced. We have adopted the 30-inch Special Cylinder,believing it to be preferable to those of largerdiameter. 30

Text Appearing After Image:

21CLEANING TRUNK. On the opposite page is shown a 10-ft. sectionof Atitojnatic Cleaning Trunk. It is usual to installtwo of these sections, making 20 ft., and to suspendsame from the ceiling. The cotton passes over Transverse Grids A andthe leaf and dirt drop between the Grids into aseries of compartments B, which are automaticallycleaned out by air draft from a Fan. Each com-partment has a hinged door or bottom C, whichwhen dropped leaves an opening into the exhaustair pipe D. The hinged doors are dropped one ata time, and the openings are shown at G. The Fan is connected to the exhaust air pipe D,and is only running while the Trunk is beingcleaned. The removable doors E give access to the topof the Trunk, and the brackets F are for thesupporting rods. One of the advantages of this Trunk is that itcan be hung from the ceiling out of the way andnot occupy valuable floor space. It is carefullybuilt and the joints of the doors are covered withleather to prevent leaks. Page 59 shows a sy

Note About Images

Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability – coloration and appearance of these illustrations may not perfectly resemble the original work.

World’s largest, heaviest operational steam locomotive – digitized Slide film

Image by Alan Vernon.

Union Pacific 3985 is a 4-6-6-4 steam locomotive built in 1943 by the American Locomotive Company. Retired around 1962, it was upgraded from a coal to an oil burning unit in 1990 to prevent ashes causing fires along the tracks. Here, the locomotive is clearing the summit of the Cajon pass in California.

Photo shot in 2000 using a Canon EOS3 camera and Velvia 100 iso Slide film.

Image – Copyright 2013 Alan Vernon