A few nice prototype manufacturing China company images I found:

Steven F. Udvar-Hazy Center: X-35B Joint Strike Fighter, A-6E Intruder, F-4S Phantom II, Sikorsky UH-34D Seahorse, UH-1H Iroquois “Huey” Smokey III, F-105D Thunderchief, F4U-1D Corsair, P-40E, SR-71 Blackbird, et al

Image by Chris Devers

Quoting Smithsonian National Air and Space Museum | Lockheed Martin X-35B STOVL:

This aircraft is the first X-35 ever built. It was originally the X-35A and was modified to include the lift-fan engine for testing of the STOVL concept. Among its many test records, this aircraft was the first in history to achieve a short takeoff, level supersonic dash, and vertical landing in a single flight. It is also the first aircraft to fly using a shaft-driven lift-fan propulsion system. The X-35B flight test program was one of the shortest, most effective in history, lasting from June 23, 2001 to August 6, 2001.

The lift-fan propulsion system is now displayed next to the X-35B at the Steven F. Udvar-Hazy Center near Dulles Airport.

On July 7, 2006, the production model F-35 was officially named F-35 Lightning II by T. Michael Moseley, Chief of Staff USAF.

Transferred from the United States Air Force.

Date:

2001

Dimensions:

Wing span: 10.05 m (33 ft 0 in)

Length: 15.47 m (50 ft 9 in)

Height: approximately 5 m (15 ft 0 in)

Weight: approximately 35,000 lb.

Materials:

Composite material aircraft skin, alternating steel and titanium spars. Single-engine, single-seat configuration includes lift-fan and steering bars for vertical flight.

Physical Description:

Short takeoff/vertical landing variant to be used by U.S. Air Force, U.S. Marines and the United Kingdom, equipped with a shaft-driven lift fan propulsion system which enables the aircraft to take off from a short runway or small aircraft carrier and to land vertically.

Engine: Pratt & Whitney JSF 119-PW-611 turbofan deflects thrust downward for short takeoff/vertical landing capability. The Air Force and Navy versions use a thrust-vectoring exhaust nozzle. The Marine Corps and Royal Air Force/Navy version has a swivel-duct nozzle; an engine-driven fan behind the cockpit and air-reaction control valves in the wings to provide stability at low speeds.

Other major subcontractors are Rolls Royce and BAE.

• • • • •

Quoting Smithsonian National Air and Space Museum | Grumman A-6E Intruder:

The Navy’s experience in the Korean War showed the need for a new long-range strike aircraft with high subsonic performance at very low altitude–an aircraft that could penetrate enemy defenses and find and destroy small targets in any weather. The Grumman A-6 Intruder was designed with these needs in mind. The Intruder first flew in 1960 and was delivered to the Navy in 1963 and the Marine Corps in 1964.

The Navy accepted this airplane as an "A" model in 1968. It served under harsh combat conditions in the skies over Vietnam and is a veteran of the 1991 Desert Storm campaign, when it flew missions during the first 72 hours of the war. It has accumulated more than 7,500 flying hours, over 6,500 landings, 767 carrier landings, and 712 catapult launches.

Transferred from the United States Navy, Office of the Secretary

Date:

1960

Country of Origin:

United States of America

Dimensions:

Overall: 16ft 2in. x 52ft 12in. x 54ft 9in., 26745.8lb. (4.928m x 16.154m x 16.688m, 12131.8kg)

Materials:

Conventional all-metal, graphite/epoxy wing (retrofit), aluminium control surfaces, titanium high-strength fittings (wing-fold).

Physical Description:

Dual place (side by side), twin-engine, all-weather attack aircraft; multiple variants.

• • • • •

Quoting Smithsonian National Air and Space Museum | McDonnell F-4S Phantom II:

The U.S. Air Force, Navy, and Marine Corps and the air forces of 12 other nations have flown the multi-role Phantom II. In this aircraft, then a Navy F-4J, on June 21, 1972, Cmdr. S. C. Flynn and his radar intercept officer, Lt. W. H. John, spotted three enemy MiG fighters off the coast of Vietnam and shot down one MiG-21 with a Sidewinder air-to-air missile. This Phantom also flew combat air patrols and bombing missions during the Linebacker II bombing campaign that same year.

Later assigned to the Marine Corps, this F-4J was extensively modernized and designated an F-4S. Changes included improving the engines (smokeless), hydraulics, electronics, and wiring; modifying the wings to increase maneuverability; and adding a radar homing and warning antenna, as well as formation tape lights on the fuselage and vertical tail.

Transferred from the United States Navy.

Manufacturer:

McDonnell Douglas Corporation

Date:

1958

Country of Origin:

United States of America

Dimensions:

Overall: 16ft 3in. x 38ft 5in. x 58ft 3in., 39999.6lb. (4.953m x 11.709m x 17.755m, 18143.7kg)

Other: 58ft 3in. x 16ft 3in. x 38ft 5in. (17.755m x 4.953m x 11.709m)

Materials:

All metal, semi-monocoque structure

Physical Description:

Twin-turbojet (J79-GE-8), two-seat (tandem) fighter / bomber. All metal, semi-monocoque structure. Cantilever, low-wing, monoplane. Dog-toothed leading edge of wing (12 degrees), anhedral tail (23 degrees).

• • • • •

Quoting Smithsonian National Air and Space Museum | Republic F-105D Thunderchief :

The F-105 was designed as a supersonic, single-seat, fighter-bomber capable of carrying nuclear weapons or heavy bomb loads at supersonic speeds. The F-105D variant was an all-weather fighter-bomber version, fitted with mono-pulse and Doppler radar for night or bad weather operations. The original weapons bay, designed for nuclear stores, was sealed and fitted with additional fuel tanks. Bombs were carried on multiple weapons racks on the centerline of the fuselage, and on wing pylons. The aircraft was fitted with a retractable in-flight refueling probe. The first F-105D flew on 9 June 1959 and 610 F-105Ds were eventually built.

This aircraft has served in several F-105 units around the world and is restored to its 1967 Vietnam-era 388th Tactical Fighter Wing, 421st Tactical Fighter Squadron camouflage as it flew during its assignment to Korat RTAB, Thailand. This jet also was briefly assigned to the 355 TFW located at Takhli RTAB in 1968. After this "Thud" finished its combat tour-which certainly included missions supporting Operation "Rolling Thunder," "Steel Tiger," and "Barrel Roll"-it returned stateside and began more than a decade assigned to the District of Columbia Air National Guard and was transferred to the Air and Space Museum in late 1981.

Transferred from the United States Air Force.

Manufacturer:

Republic Aviation Corporation

Date:

1961

Country of Origin:

United States of America

Dimensions:

Overall: 19ft 8in., 26854.8lb. (5.994m, 12181.2kg)

Other: 19ft 8in. x 64ft 5in. x 34ft 11in. (5.994m x 19.634m x 10.642m)

Materials:

All metal monoplane, supersonic single-engine jet fighter.

Physical Description:

Single-seat, single-engine, jet, fighter/bomber; USAF.

• • • • •

Beginning in 1962, the H-34 served as the primary Marine Corps assault helicopter of the Vietnam War until its replacement by the turbine-powered CH-46. It began in 1952 as a Navy anti-submarine warfare helicopter evolved from the Sikorsky S-55 series. Initially designated as the HSS-1, it would also go on to see significant service in the combat assault and utility roles with the Army and Marine Corps. Great Britain and France also deployed versions in some of the first helicopter combat assault operations.

A large payload capacity and generous center-of-gravity range made the H-34 series an effective transport helicopter for the1950s. Its weaknesses were a reciprocating engine that struggled in the heat and humidity of Southeast Asia and maintenance intensive mechanical components. This Marine Corps UH-34D never served overseas, but wears the markings of Marine Medium Helicopter Squadron 163 that did see extensive combat in Vietnam.

Transferred from the United States Marine Corps

Manufacturer:

Sikorsky Aircraft

Country of Origin:

United States of America

Physical Description:

All equipment that came with the helicopter that is not attached to it is contained in box A19750823002 with the exception of two items. The VIP steps that attach to the side of the aircraft and the long-handled tool to assist with main rotor blade deployment are stored inside the helicopter’s cabin.

• • • • •

Quoting Smithsonian National Air and Space Museum | Bell UH-1H Iroquois "Huey" Smokey III:

In 1956, the Iroquois, commonly known as the Huey, first flew as an Army replacement for the H-13 medevac helicopter of Korean War fame. By the end of the 20th century, Bell had produced more Hueys than any other American military aircraft, except for the Consolidated B-24. Superbly suited to the air mobility and medical evacuation missions in Vietnam, the Huey became an indelible symbol of that conflict.

This UH-1 compiled a distinguished combat record in Vietnam from 1966 to 1970 with four units, including the 229th Assault Helicopter Battalion of the 1st Cavalry and the 118th and 128th Assault Helicopter Companies. Numerous patches on its skin attest to the ferocity of missions flown while operating as a "Smoke Ship," laying down smokescreens for air assault operations with the 11th Combat Aviation Battalion.

Transferred from the United States Army Aviation Museum

Manufacturer:

Bell Helicopter Company

Date:

1966

Country of Origin:

United States of America

Dimensions:

Rotor Diameter: 14.7 m (48 ft 3 in)

Length: 12.6 m (41 ft 5 in)

Height: 4.2 m (13 ft 7 in)

Weight, empty: 2,580 kg (5,687 lb)

Weight, gross: 4,309 kg (9,500 lb)

Materials:

Overall: Metal airframe, plexiglass windows.

Physical Description:

Utility helicopter, two-blade main and tail rotors, powered by a single GE T-53L13BA turbo-shaft engine. There are oil stains on the lower aft fuselage and beneath the tail rotor gear box. The horizontal stabilizer was removed.

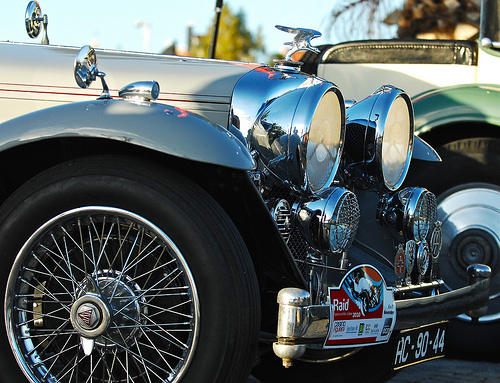

Alvis Speed 20 Tourer 1932

Image by pedrosimoes7

Belem, Lisbon, Portugal

in Wikipedia

Alvis cars were produced by the manufacturer Alvis Car and Engineering China Company Ltd of Coventry, United Kingdom from 1919 to 1967. The company also produced aero-engines and military vehicles, the latter continuing long after car production ceased.

Beginnings

The original company, TG John and Co. Ltd., was founded in 1919. Its first products were stationary engines, carburettor bodies and motorscooters. The company’s founder T.G. John was approached by Geoffrey de Freville with designs for a 4-cylinder engine with aluminium pistons and pressure lubrication, unusual for the period. Some have suggested that de Freville proposed the name Alvis as a compound of the words "aluminium" and "vis" (meaning "strength" in Latin) although de Freville himself vigorously denied this theory. Perhaps the name was derived from the Norse mythological weaponsmith, Alvíss, but the true origin is unknown.

The first car model, the 10/30, using de Freville’s design was an instant success and set the reputation for quality and performance for which the company became famous. Following complaints from the Avro aviation company whose logo bore similarities to the original winged green triangle, the more familiar inverted red triangle incorporating the word ‘Alvis’ evolved. In 1921, the company changed its name and became the Alvis Car and Engineering China Company Ltd. and moved production to Holyhead Road, Coventry where from 1922 to 1923 they also made the Buckingham car.

In 1923 Captain GT Smith-Clarke joined from Daimler as Chief Engineer and Works Manager and was soon joined by WM Dunn as Chief Draughtsman. This partnership lasted for 25 years and was responsible for producing some of the most successful products in the company’s history.

The original 10/30 side-valve engine was developed progressively becoming by 1923 the famous overhead-valve 12/50, produced until 1932 and one of the most successful vintage sports cars of all time. Exhilarating performance and rugged reliability meant that around 350 of these 12/50 hp cars and 60 of the later (and latterly concurrent) 12/60 hp survive today representing some 10 percent of total production.

1927 saw the introduction of the six-cylinder 14.75 h.p. and this engine became the basis for the long line of luxurious six-cylinder Alvis cars produced up to the outbreak of war. Not only were these cars extremely elegant but they were full of technical innovations. Independent front suspension and the world’s first all-synchromesh gearbox came in 1933 followed by servo assisted brakes. A front wheel drive model was introduced (from 1928 to 1930), a model bristling with innovation with front wheel drive, in-board brakes, overhead camshaft and, as an option, a Roots type supercharger.

Smith-Clarke designed remarkable models during the 1930s and 1940s — including the handsome, low-slung six-cylinder Speed 20, the Speed 25 (considered by many to be one of the finest cars produced in the 1930s) and the 4.3 Litre model. As with many upmarket engineering China companies of the time Alvis did not produce their own coachwork relying instead on the many available Midlands coachbuilders such as Cross and Ellis, Charlesworth and Vanden Plas. Several cars also survive with quite exotic one-off bodywork from other designers. In 1936, the company name was changed to Alvis Ltd and by the beginning of the war, aero-engine and armoured vehicle divisions had been added to the company.

World War Two

In September 1939 following the outbreak of war car production was suspended, but was later allowed to resume and production of the 12/70, Silver Crest, Speed 25, and 4.3 Litre continued well into 1940. During World War II the car factory was severely damaged in the German Luftwaffe raid on Coventry in 1940 though strangely the armaments factory emerged fairly unscathed. Much valuable gear cutting China and other equipment was lost and car production was suspended for the duration of the war only resuming during the latter part of 1946. Despite this, Alvis carried out war production on aero engines (as sub-contractor of Rolls-Royce) and other aeroplane equipment.

Post war

Car production resumed with a four-cylinder model, the TA14, based on the pre-war 12/70. A solid, reliable and attractive car, the TA14 fitted well the mood of sober austerity in post war Britain, but much of the magic attaching to the powerful and sporting pre-war models had gone and life was not easy for a specialist car manufacturer. Not only had Alvis lost their car factory but many of the prewar coachbuilders had not survived either and those that had were quickly acquired by other manufacturers. In fact, the post war history of Alvis is dominated by the quest for reliable and reasonably priced coachwork.

Smith-Clarke himself retired in 1950 and Dunn took over as chief engineer. In 1950 a new chassis and six-cylinder 3 litre engine was announced and this highly successful engine became the basis of all Alvis models until production ceased in 1967. Saloon bodies for the TA21, as the new model was called, again came from Mulliners of Birmingham as they had for the TA14, with Tickford producing the dropheads. But with the first of these becoming part of Standard Triumph and the second being acquired by Aston Martin Lagonda, it was clear by 1954 that new arrangements would have to be made. By this time some of the most original and beautiful designs on the three litre chassis were being produced by master coachbuilder Hermann Graber of Switzerland and indeed these one-off designed cars are highly sought after today. With a licence in place, from 1955 all Alvis bodies became based on Graber designs. Early examples, the TC108/G, were built by Willowbrook of Loughborough but at such a high price that very few were made. Only after 1958 with the launch of the TD21 did something resembling full scale production resume as Park Ward, coachbuilders for Rolls-Royce and Bentley, contracted to build the bodies at a much lower price. These cars, the TD21 and its later variants, the TE21 and finally the TF21 are well built, attractive and fast cars. However it was clear by the mid sixties that with a price tag of nearly double that of the mass produced Jaguar the end could not be far off.

There were several ‘might-have-beens.’ From 1952 to 1955 Alec Issigonis, the creator of the later Mini worked for Alvis and designed a new model with a V8 engine which proved too expensive to produce.

Rover took a controlling interest in Alvis in 1965 and a Rover-designed mid-engined V8 coupé prototype named the P6BS was rumoured to be the new Alvis model but with the takeover by British Leyland this too was shelved. By the time the TF21 was launched in 1966, (available, like its predecessors in both saloon and drophead form and with either manual or automatic gearbox), the model was beginning to show its age despite a top speed of 127 mph – the fastest Alvis ever produced. With only 109 sold and with political troubles aplenty in the UK car manufacturing China business at that time, production finally ceased in 1967. In 1968, a management buyout was finalised and all the Alvis design plans, customer records, stock of parts and remaining employees were transferred to Red Triangle. The Alvis name lived on with armoured fighting vehicle production.

Modern

Main article: Alvis plc

As part of Rover, Alvis Limited was incorporated into British Leyland but was bought by United Scientific Holdings plc in 1981. Subsequently the company’s name changed to Alvis plc. In 1998, the armoured vehicle business of GKN plc was taken on and the main UK manufacturing China operation moved from Coventry to Telford. The site of the Alvis works in Holyhead Road is now an out-of-town shopping complex, but its name, Alvis Retail Park, reflects the heritage of the site.

In 2002 Alvis group purchased Vickers to form the subsidiary Alvis Vickers Ltd which was subsequently purchased by BAE Systems in 2004. BAE Systems ended the use of the Alvis distinctive ‘red triangle’ trademark.

In 2009, Red Triangle negotiated the legal transfer of the Alvis car trademarks and in 2010 announced the very desirable 4.3-Litre Short Chassis tourer would once again be available. All Alvis’ records remain intact at the company’s Kenilworth headquarters along with a large stock of period parts. Amazingly, one of the men to have worked on the very last Alvis car produced in 1967 is still retained by the company in a training capacity.

Built to the original plans, the new car has been named the ‘Continuation Series’ to reflect the 73-year interruption in its production between 1937 and 2010. It differs only in detail from the pre-war examples: for emissions, the engine is governed by an Electronic Fuel Injection system with electric ignition, brakes are hydraulic rather than cable, the steering column collapsible and the rear light arrangement reconfigured to conform to modern standards.