A few nice cnc production images I found:

BrickArms Brodie Helmet Development – Prototype, First Article, and Final Production Samples

Image by enigmabadger

Organizing my collection the other day, I realized I had samples of every step of development of the BrickArms Brodie Helmet, so I thought I’d take some pictures to document the development of this accessory:

Prototype – Used to test Will’s CAD design. Created using hand-injection of an aluminum prototype mold Will cut using his personal CNC.

Eventually, Will submitted this design as well as other helmet designs to his tooler for work to begin on the production mold to create new BrickArms headgear

First Article – Created from the new solid steel, professionally-tooled production mold (called a "tool" in production terminology) as it was being developed to ensure the parts are exact to the Will’s designs and function as need (correct fits, grips, etc). Based on testing of the first articles, Will then communicates with the tooler for any additional work that needs to be done to the tool (recutting, polishing).

First articles are not prototypes; at that point in the production process, the design itself is finalized, and the mold used to produce them is tool from which the production parts will be created. Articles aren’t tests of designs but of the tool itself.

One neat part about the above Brodie article: notice the first article lacks the matte finish of the final production part. This is because this article was created before that texture had been applied to the mold

Final Production – Once Will approves the mold for production, the tooler sends the mold to the molder and production runs of the tool in various colors can begin!

Three different accessories, each one a piece of BrickArms history!

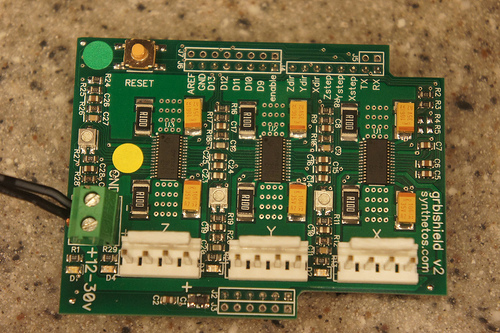

grblShield v2 Production

Image by rileyporter

This is the current version (oct 2011) of grblShield.

You can get it here: grblShield