A few nice machining forged parts images I found:

Head Buzz – Is Facebook like Crack?

Image by jurvetson

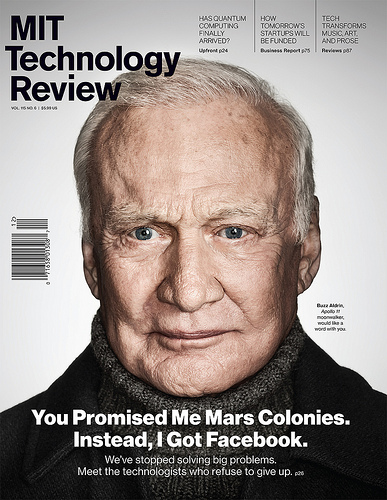

The current issue of Tech Review arrived… and the plaintive plea of Buzz Aldrin is so arresting. Why have we invested in one and not the other?

To be it seems like a surreal disconnect. Innovation is in florid bloom out there, with compounding technologies that warp the very fabric of reality. Big, bold projects to change the world… and beyond. Transportation is becoming electric and fully autonomous. New constellations of low-cost satellites will provide free imagery of every part of the Earth every day. A new wave of industrial and agriculture biotech is upon us as we move beyond cut & paste and freely write the code of life like we program a computer… and the software creates its own hardware. From a few artificial microbes, we can now create billions of novel life forms per day, with all of their DNA spooling from a gene printer. Various breakthroughs in digital non-volatile memory will take us to the post-CMOS era in computing. Humanoid robots will flow into the workforce in 2013 with more powerful AI to follow. Femtosecond lasers can machine materials with zero heat. Quantum computers can now outperform a classical computer by orders of magnitude, and may soon outperform all computers every built for certain optimization calculations and machine learning tasks.

The future is quite bright if you talk to entrepreneurs. The pace of innovation is breathtaking if you talk to scientists, continually forging the future along the frontiers of the unknown. I hope more investors can look beyond the arbitrage plays rippling throughout the information economy, so easily farmed for their short-term pops, and fleeting sense of bounty. The daily din of opportunism can create a head buzz that crowds out healthier fare.

The pattern of progress comes into focus with a longer-term perspective. We are investing in SpaceX’s trajectory to colonize Mars, to take us where no person has gone before, to venture forth to make humanity a multi-planetary species. And, as I flipped the pages, I was delighted to see that we are investing in almost every “big opportunity” highlighted in the magazine.

Black Country Living Museum – Steep cobbled path, Animal Trap Works and Brockmoor Carters

Image by ell brown

This is the Black Country Living Museum in Dudley, West Midlands.

The museum was established in 1975, and the first buildings moved here in 1976. Since then a 26 acre site has been developed, with the unique conditions of living and working in the Black Country from the mid 19th century to early 20th century.

It is off Tipton Road in Dudley.

This is Brockmoor Carters.

Horses provided the key to transport in the Black Country well into the twentieth century. They were used as draught animals to haul narrow boats loaded with goods on the canals, drag heavy coal carts and pull trams, carriages, milk floats, delivery wagons and fire engines.

Heavy horses, usually shires, like William at the Museum, were used for haulage in heavy industry. But the majority of work was done using ‘half leg’ or short legged shire cross breed horses to pull smaller two wheeled carts and canal boats as they were lighter to handle and cheaper to feed.

Trade horses were kept in fairly humble quarters in yards like this one across the Black Country.

The yard contains a stable which was carefully dismantled and moved from Ogley Hay Road at Burntwood in Cannock on the northern edge of the Black Country where it was built around 1900.

The stable fittings were donated from a stable in Handsworth Wood Road, Birmingham. The combined office and harness room are copied from buildings found in Netherton and a small feed store and simple corrugated iron lean-to cart shed complete the authentic assemblage of buildings in the yard.

On the gate it says Hauliers to John Folkes Lye Forge (Est. 1699)

Path to the right to Dudley Canal Trust Boat Trips

We never got to go down there as we decided to head through the last section of the village, then went around the Canal Arm instead.

Up ahead is a steep cobbled path.

Wheel chair on left.

Also the Darby Hand Chapel.

Up here is the Animal Trap Works.

Sidebotham’s Trap Works, originally constructed in Wednesfield, near Wolverhampton in 1913, is a typical example of a small purpose built factory of the period.

Wednesfield was a major centre for the manufacture and worldwide export of small animal traps. The stencils hanging from the Belfast Truss roof were used to label the packing cases with destinations of ports in Australia, Africa, South America and many other far-flung destinations.

The stamping, pressing and punching machines are driven by lineshafting from a single cylinder gas engine of 1906, built by Tangye’s of Smethwick.

The forge hearth was used to make the springs which operated the traps and parts were assembled on benches using the hand-operated fly presses, before being painted or ‘blacked’ in tanks by the canalside wall and packed for delivery.