Verify out these precise machining photos:

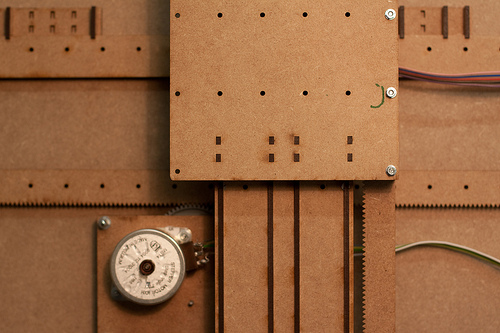

Lased XY Table – Version 1.

Image by Quasimondo

This is my very first try at developing a XY table. The goals here are to use as small purchased parts as feasible (so I can begin constructing and do not have to wait for delivery) and to preserve the charges down. Which signifies that there are certainly ways to make it smaller or much more precise, but that generally includes making use of metal axes or gear belts.

This one particular uses two really inexpensive steppers (can not say no to €0,95 per piece) that unfortunately have only 48 methods per revolution which tends to make it needed to use a gear box to get a greater resolution. So for now I am receiving ~three measures per mm which is about 75 dpi. There is of course a tradeoff amongst acquiring a higher resolution and the maximum speed I can move the table, so for my purposes 75 dpi are okay.

For the gears I was lazy and utilized the ones we had lying about in the Fablab – I could lase those as effectively.

The base is presently moving on two tracks with steel balls but I will modify that to ball bearings like the ones I am making use of for the prime sled (I just ran out of bearings).

The steppers are controlled with an Arduino through two ULN 2003 Darlington arrays.

So the expenses for this one are presently anything like

Wood (3mm HDF): ~€5,00

two Steppers: €1,90

Gears: ~€3,00

Electronic components (w/o Arduino): €3,00

4 Ball bearings: €3,00

Steel balls: ~€2,00

Screws, Bolts, Axes: ~€1,00

So for about €20,- I feel it really is not too shabby.

Lased XY Table – Version 1.

Image by Quasimondo

This is my initial try at building a XY table. The targets here are to use as tiny purchased parts as possible (so I can commence building and do not have to wait for delivery) and to maintain the costs down. Which indicates that there are certainly ways to make it smaller sized or a lot more precise, but that normally entails using metal axes or gear belts.

This a single uses two quite low-cost steppers (can’t say no to €0,95 per piece) that regrettably have only 48 methods per revolution which makes it needed to use a gear box to get a larger resolution. So for now I am getting ~three methods per mm which is about 75 dpi. There is of course a tradeoff amongst getting a larger resolution and the maximum speed I can move the table, so for my purposes 75 dpi are okay.

For the gears I was lazy and used the ones we had lying about in the Fablab – I could lase those as properly.

The base is at the moment moving on two tracks with steel balls but I will alter that to ball bearings like the ones I am using for the leading sled (I just ran out of bearings).

The steppers are controlled with an Arduino by way of two ULN 2003 Darlington arrays.

So the charges for this one are currently some thing like

Wood (3mm HDF): ~€5,00

2 Steppers: €1,90

Gears: ~€3,00

Electronic components (w/o Arduino): €3,00

4 Ball bearings: €3,00

Steel balls: ~€2,00

Screws, Bolts, Axes: ~€1,00

So for about €20,- I think it is not too shabby.

A present

Image by scrappy annie

I dislike the process of producing a quilt as the precise nature of patchwork seems to be foreign to my nature.

However, occasionally a quilt is the only attainable gift for a specific occasion. This was a single of them.

I created the quilt from some indigo dyed calico I created a although ago, and pieced and machine embroidered it.

Alison Francis helped me with the binding, thank goodness. Every time I make a quilt I say "Never Once more" and this time I really mean it!